Wool spinning

The role of the spinner is to select the best suited wool for weaving, to produce a thread corresponding to the required level of quality for Aubusson tapestries.

Handmade spinning suits very well smaller orders from artistic professions, such as weavers: the thread thickness is adapted to its weaving use (25 to 26 micrometer).

The wool sometimes comes from New-Zealand or Australia, but for some specific realizations, in order to match at best with the weaver’s demand, the spinner could rather use the products of a French wool worker. Creuse and Limousin are thought of as historical ovine breeding territories. The breeders and the wool craftsman always integrate in this sector.

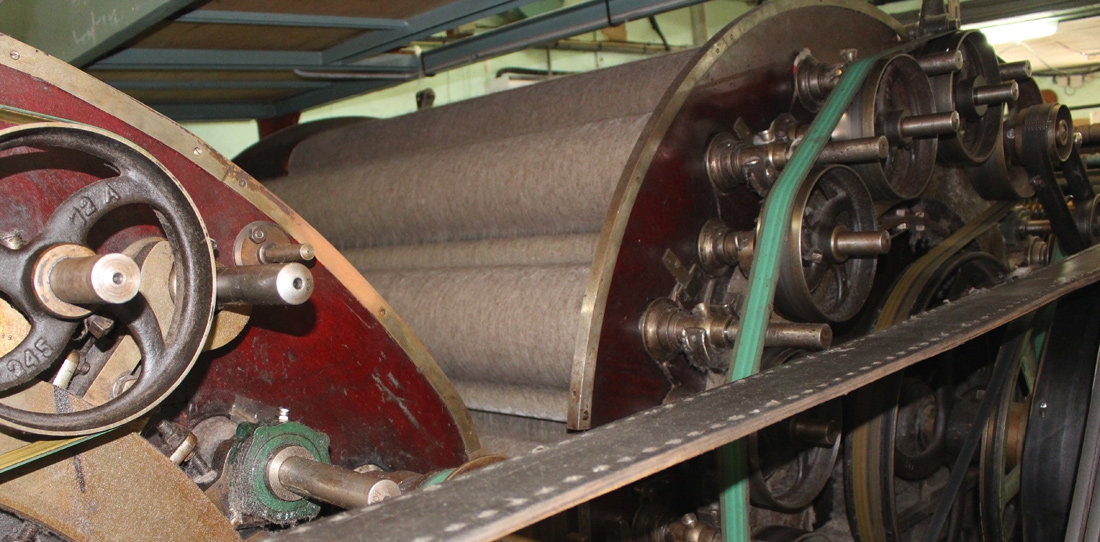

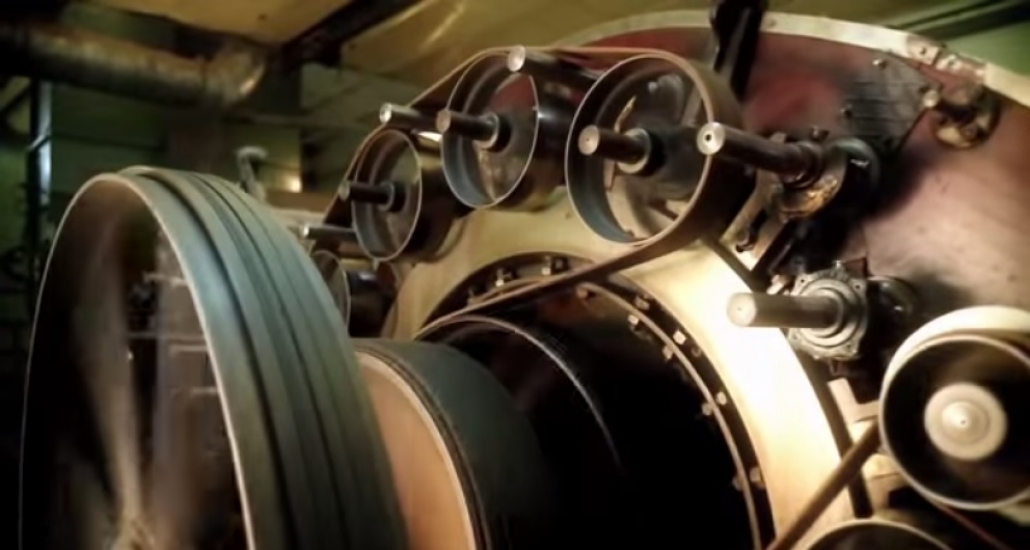

The first step of the spinning is the carding, where the wool is detangled when going through the drums of the card. Filled with very thin steel peaks and turning at full speed, the card allows dividing and paralleling the wool fibers. Following the size of the fiber and the destination of the thread, the wool is spun directly coming out the card or, in the case of extra fine wool, combed once more.

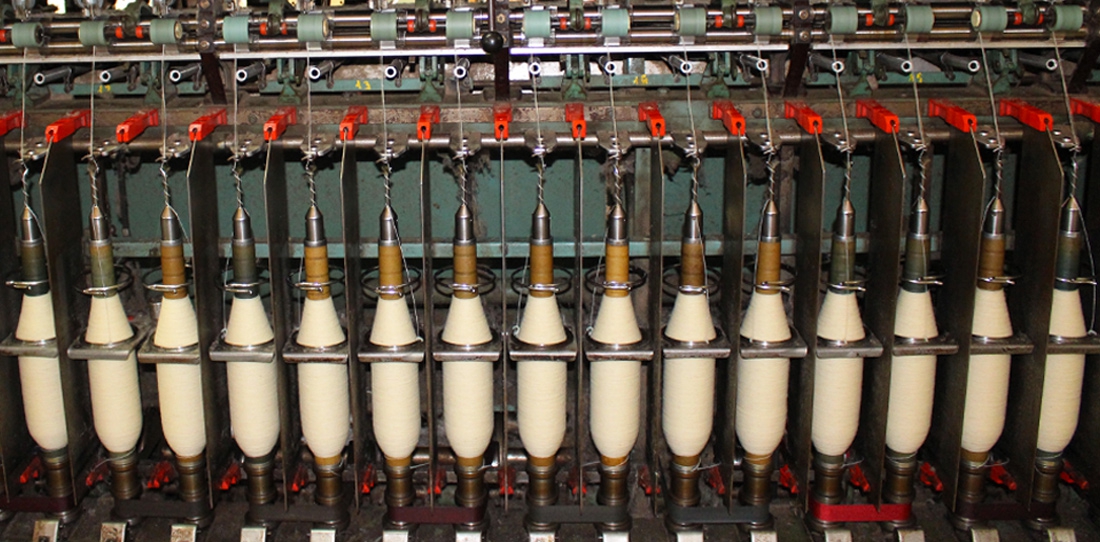

Strands and ribbons of wool are then obtained and will be turned into yarns. It is now time to stretch them on the spinning frame to refine them progressively. This step is called roving and at this point, the obtained thread is not resistant at all and can be ripped off by only pulling on it. It is actually the twist born from the threading with a couple other strands which increases its resistance and make it more regular (the ply yarns).

Thin, rather elastic and warped, the yarn is generally white or off-white (except in the case of naturally brown or black wool) and can thus goes to the vat of dye.